- About Us

-

- Galvanizing Furnace

- Galvanizing Zinc Tank

- Drier

- Acid Fume Extraction System

- Zinc Fume Extraction System

- Flux Filtration System

- Flux Heating System

- Acid Filtration System

- Pre-treatment Process Tanks

- Post Treatments Tanks

- Effluent Treatment Plant (ETP)

- Enclosed Pre-treatment Room

- Auxiliary Equipment

- Chemical Storage Tank

- Centrifugal Hot Dip Galvanizing

-

- Complete Plant Design & Layout

- Galvanizing Process Design & Optimization

- Galvanizing Plant Machinery Installation & Commissioning

- Galvanizing Plant Maintenance

- Plant Supervision Control Systems

- Plant Safety & Automation

- Provide Manpower For Galvanizing Plant

- Production Data Management & Analysis

- Process Tank Repair

- Spare Parts Supply

- 24×7 Support

- Post Commissioning Support

- Training & Development

- Galvanizing Zinc Kettle Replacement

- Hot Dip Galvanizing Plant Upgradation

- Selection Of Production Team For Galvanizing Plant

- Quality Testing Laboratory Setup

- Hot Dip Galvanizing Job Work

Acid Fume Extraction System

Cleaner Air, Safer Workplaces – Innovative Fume Control Solutions by Gunatit Engineers

At Gunatit Engineers, we are dedicated to pioneering innovative solutions for the hot-dip galvanizing industry tackling air pollution challenges with cutting-edge technology. One of the major issues in this industry is the hazardous fumes generated during the steel surface cleaning process.

These acidic vapours, if left unchecked, can spread to the floor and contaminate the environment, posing a serious risk to both the workplace and the workers’ health. Our advanced systems effectively capture and absorb hazardous fumes generated during the steel cleaning process in pickling tanks, ensuring a cleaner, safer work environment.

When materials are dipped for surface cleaning, acidic fumes are released. Our systems, including Lip-Type Ducting and Fully Enclosed Pre-Treatment Plants, are specifically designed to capture these fumes at the source, helping to protect your facility, employees, and the environment.

Customized Solutions for Clean Air

Each facility has unique requirements based on budget and operational needs. That’s why we offer two highly effective systems designed to prevent the spread of acidic fumes and maintain a clean environment.

Lip-Type Ducting System

Fully Enclosed Pre-Treatment Plant

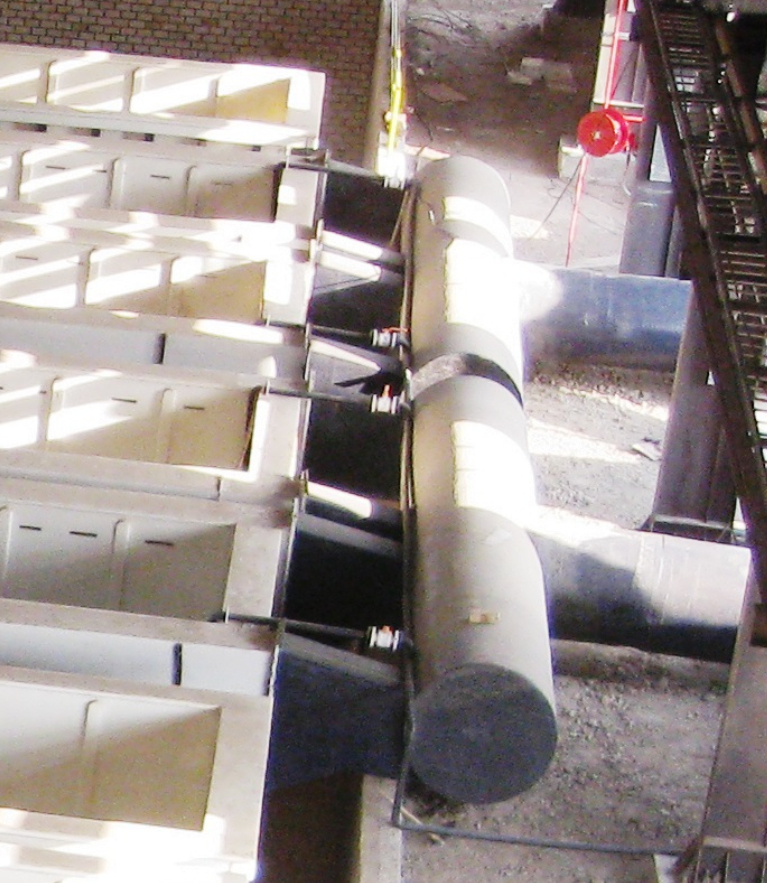

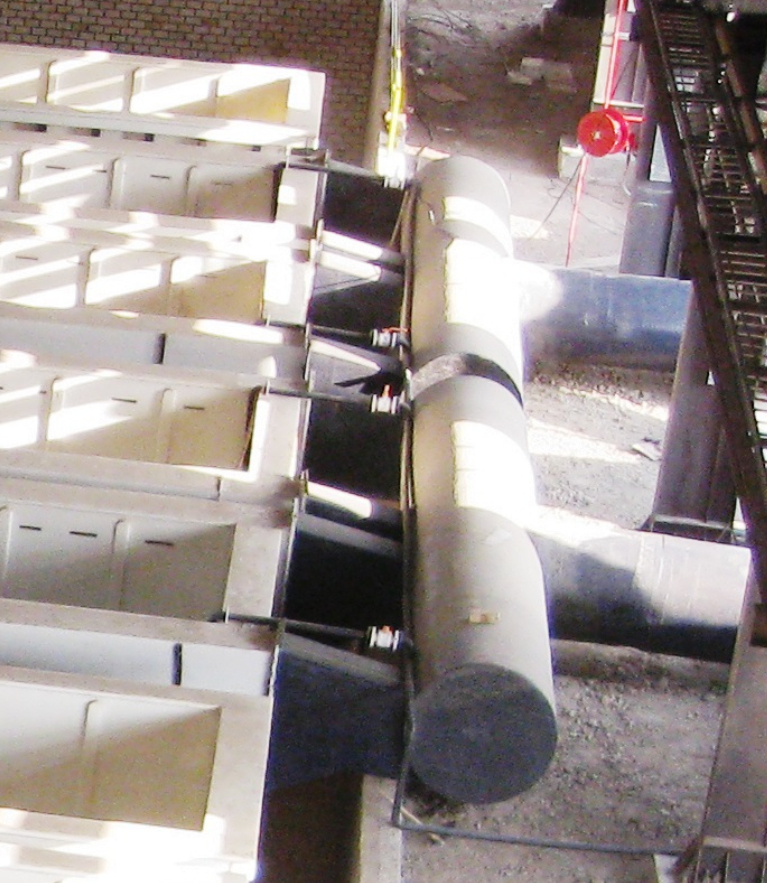

Lip-Type Ducting System

The Lip-Type Ducting system is integrated directly into the P.P. pickling tanks and positioned laterally over the process tank sides. This system is specifically designed to maximize the acidic fume capture at the source.

- Seamlessly integrated with P.P. Pickling Tanks.

- Lateral Ducting Design for maximum fume absorption efficiency.

- Efficient Scrubbing System: Acidic fumes are directed through ducts and header to the scrubber, where they are neutralized before being released, ensuring clean air.

This system is ideal for facilities looking for a space-saving, and cost-effective solution.

- Seamlessly integrated with P.P. Pickling Tanks.

- Lateral Ducting Design for maximum fume absorption efficiency.

- Efficient Scrubbing System: Acidic fumes are directed through ducts and header to the scrubber, where they are neutralized before being released, ensuring clean air.

This system is ideal for facilities looking for a space-saving, and cost-effective solution.

Fully Enclosed Pre-Process Treatment Plant

For comprehensive air pollution control, the Fully Enclosed Chemical Process Treatment Plant offers the ultimate solution. The entire pre-treatment area is enclosed with high-quality acid-proof materials such as PVC, PP, and PE, preventing acidic fumes from escaping into the environment.

- Complete Area Enclosure: Fully enclosed pre-treatment tanks create a controlled environment.

- Acid-Proof Materials: High-quality PVC, PP, and PE materials protect against corrosion.

- Clean Environment: The enclosed design ensures no acidic fumes escape, improving air quality and protecting your building’s infrastructure.

This system is ideal for facilities maximum protection from acidic fumes, offering a long-term and sustainable solution.

- Protect Your Facility: Prevent corrosion and damage to your building by capturing acidic fumes.

- Ensure a Safe Work Environment: Maintain air quality and protect your workforce from hazardous vapours.

- Customized Solutions: Choose from different systems based on your needs and budge.

- Complete Area Enclosure: Fully enclosed pre-treatment tanks create a controlled environment.

- Acid-Proof Materials: High-quality PVC, PP, and PE materials protect against corrosion.

- Clean Environment: The enclosed design ensures no acidic fumes escape, improving air quality and protecting your building’s infrastructure.

This system is ideal for facilities maximum protection from acidic fumes, offering a long-term and sustainable solution.

- Protect Your Facility: Prevent corrosion and damage to your building by capturing acidic fumes.

- Ensure a Safe Work Environment: Maintain air quality and protect your workforce from hazardous vapours.

- Customized Solutions: Choose from different systems based on your needs and budge.